Tutorial

SAP user tutorial purpose and some configuration like: SA BO, BI etc

Monday, June 10, 2024

Period 003/2024 is closed in company code CJSK, ledger 0L, transaction type RKU1

Monday, June 3, 2024

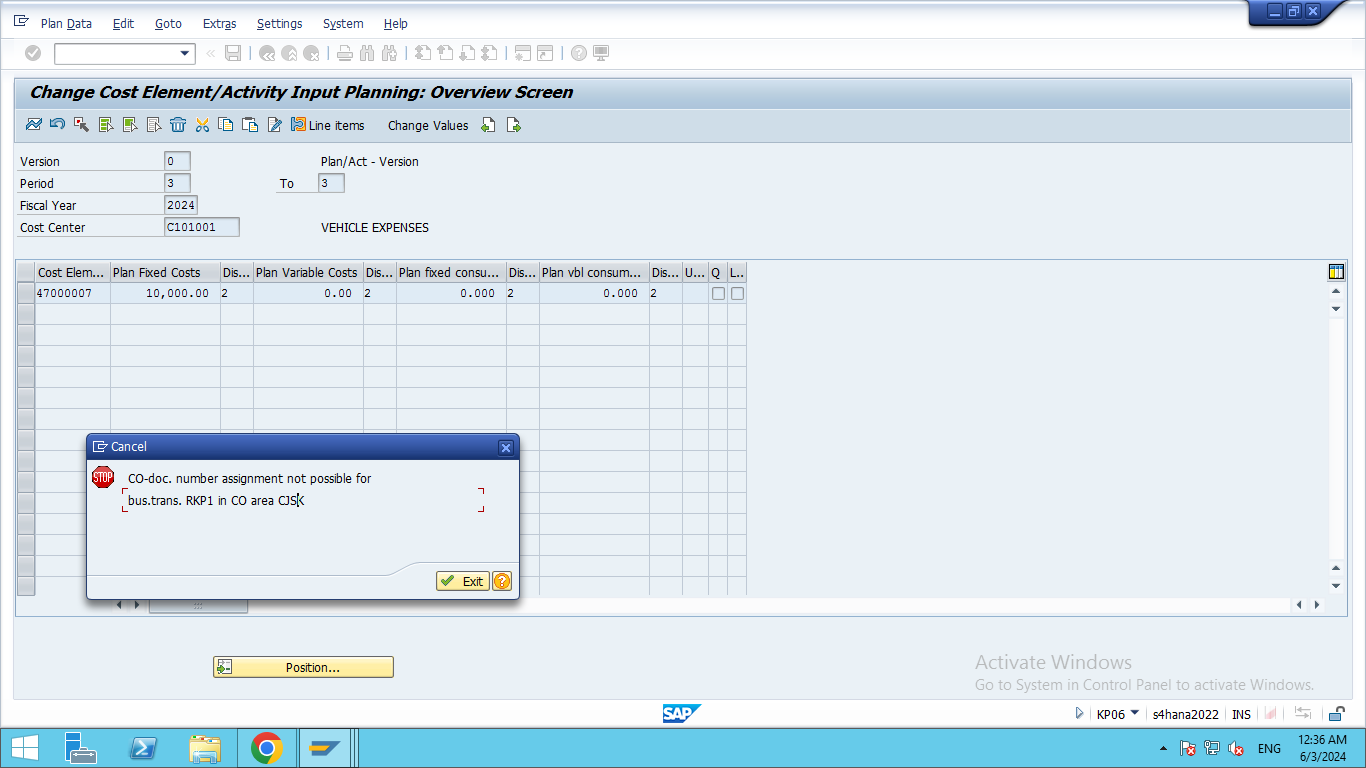

CO-doc. number assignment not possible for bus.trans. RKP1 in CO area CJSK

This Error showing During post KP06 transaction.

Solution:

Maintain Number range for CO document RKP1 Element using Tcode: KANK

Wednesday, May 22, 2024

Company code not assigned to C/R or C/R to calculation procedure

How to resolve below error

first check your country code & check Procedure select or not if not so put your pricing procedure in your country code.

Tuesday, May 21, 2024

Customer/Vendor/GL Delete permanently in S/4HANA

Use Tcode: OBR2

Saturday, May 11, 2024

How to check Product cost Marked or not/Released or not using Table: KEKO (Product Costing - Header Data)

Step 1st :

Run Tcode SE16N then put Table Name: KEKO Execute. see below screen shot

Step 2nd:

Material Cost Marked but not released so at the time of CK40N Error showing like below.

Friday, April 26, 2024

Manually Deactivate Asset Code in SAP S4/HANA

Once an asset has been deactivated, you can no longer post to the asset (with one exception: posting a reversal of the last retirement). you can also manually change the deactivation date in the asset master record.

Step-1) Use Tcode : AS02, Enter Asset code press Enter Key, then put manually deactivation date

Step 2) If show error like below

Deactivation date earlier than last closed year 2022 (Correct)

Message no. AA295

Diagnosis

The deactivation date is in a closed fiscal year. Deactivation is only possible in a fiscal year after 2022.

e.i. : If Current FY: 2024-25 and deactivation date is 03-Mar-2020 then this error appears.

Step 3)

Use Tcode SE16N for asset code deactivation with debugging process.

Wednesday, April 24, 2024

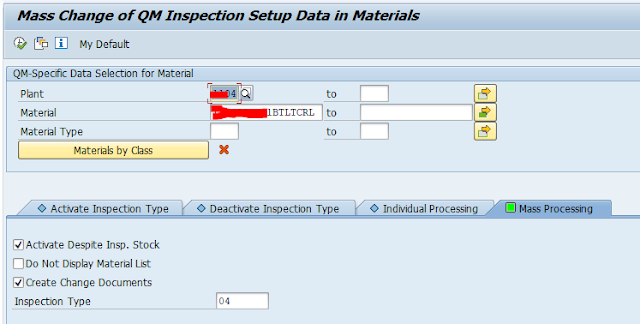

Making Mass Changes to the Inspection Setup (QM) in Material Master

Procedure

Choose Logistics -> Quality management -> Quality planning -> Logistics master data -> Material -> Inspection setup (Tcode: QA08 - Inspection Setup )

Choose Inspection setup, Mass processing.

Select the materials you want to process. You can make the selection by using the plant, material, the material type and the material class.

Enter the required inspection type.

Edit the following indicators:

Check and Press Enter

Select All and Save

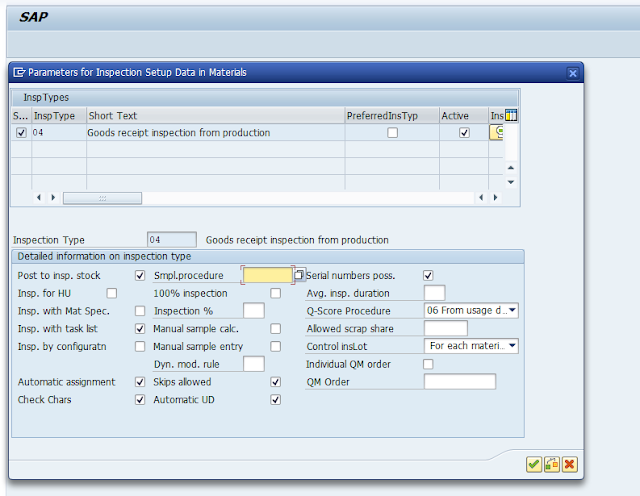

The screen for editing the inspection setup parameters in the material master is displayed.

Edit the indicators and field entries and choose Continue.

If you set the Do not display material list indicator, the data for the chosen inspection type is changed immediately for all selected materials.

If you did not set the Do not display material list indicator, select the materials from the list, for which you want to change the inspection type and choose Continue .

Save your data.